The rapid advancements in Building Information Modeling (BIM) have transformed the mechanical engineering job scope, particularly in the construction and infrastructure sectors. With complex systems like HVAC, plumbing, and fire protection requiring precision, BIM mechanical engineers are now in high demand. Adopting BIM software in the mechanical domain ensures streamlined workflows, reduced errors, and efficient collaboration among engineers, architects, and contractors.

The role of a BIM mechanical engineer extends beyond just drafting and designing. They must understand how mechanical systems interact with other building components and how to optimise their performance using BIM MEP software. Whether it's HVAC design, piping layouts, or energy efficiency analysis, BIM-related software provides powerful tools to enhance decision-making.

What Does a Mechanical Engineer Do?

A mechanical engineer’s job encompasses designing, analysing, and improving mechanical systems, ranging from HVAC units to complex industrial machinery. Job opportunities for MEP engineers exist across the automotive, aerospace, energy, and construction industries. With digitisation shaping the industry, mechanical engineers must adapt to new technologies like BIM modeling software to stay competitive.

A BIM mechanical engineer is responsible for designing, analysing, and managing mechanical systems in buildings and infrastructure projects. Some of their key duties include:

- Designing mechanical systems: Using BIM modelling software, designing HVAC, plumbing, and fire protection layouts.

- System analysis and optimisation: Evaluating performance metrics to enhance energy efficiency and reduce operational costs.

- Collaboration with multidisciplinary teams: Working with architects, structural engineers, and electrical engineers through BIM MEP software to ensure seamless integration of mechanical systems.

- Clash detection and coordination: Using BIM-related software to identify design conflicts before construction begins.

- Sustainability and compliance: Ensuring that mechanical systems adhere to energy regulations and environmental standards.

What is BIM for Mechanical Engineers?

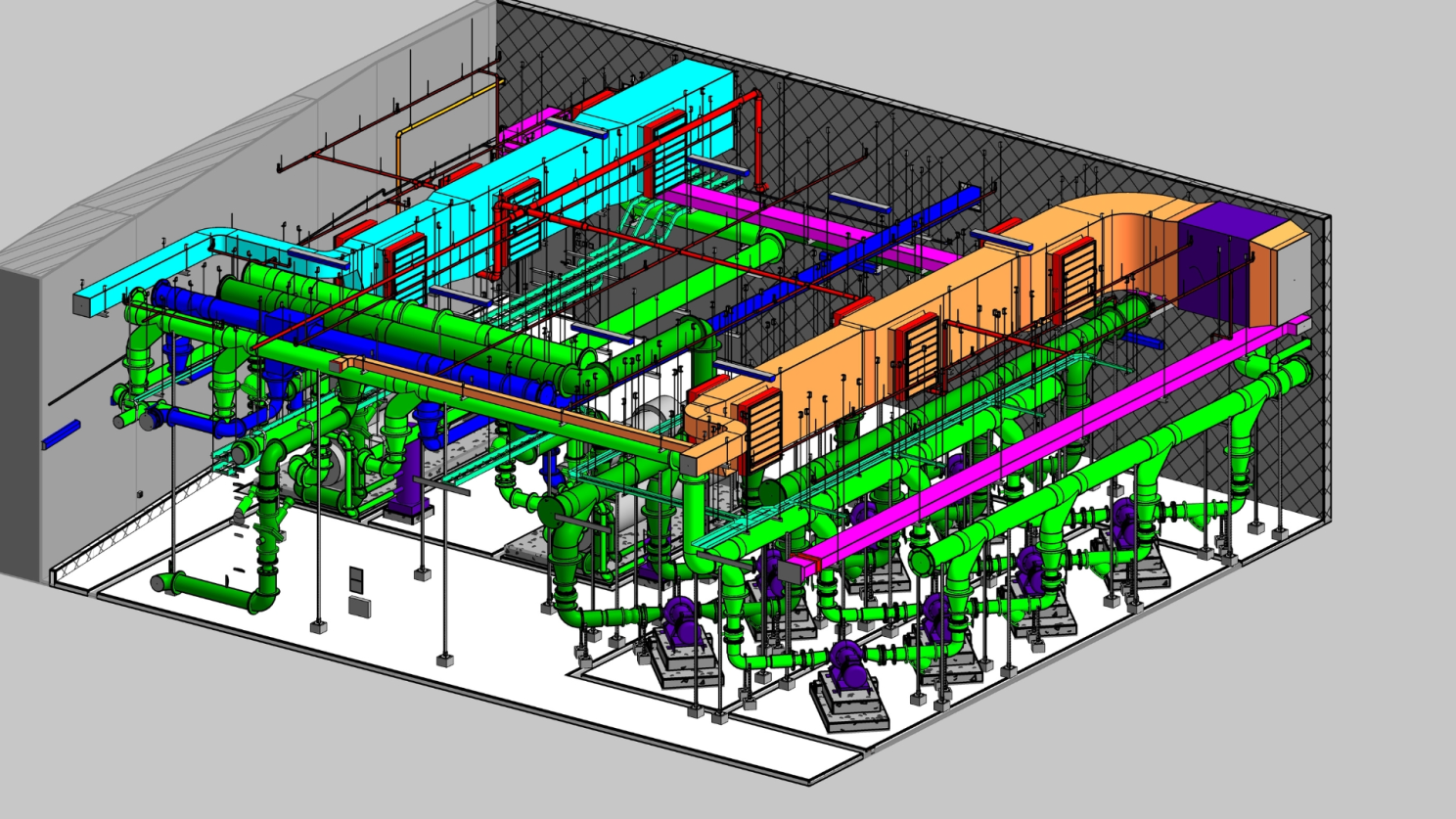

BIM mechanical refers to integrating BIM-related software into mechanical system design, allowing engineers to create intelligent 3D models of mechanical, electrical, and plumbing (MEP) components. MEP in BIM facilitates better design coordination, reducing conflicts during construction. MEP BIM modeling provides real-time data and simulation capabilities, helping engineers make informed decisions while designing mechanical systems.

MEP in BIM refers to integrating Mechanical, Electrical, and Plumbing (MEP) components into a single cohesive model. This means designing heating, ventilation, and air conditioning (HVAC) systems, piping, and fire protection systems with greater precision for mechanical engineers. MEP BIM modeling facilitates:

- Accurate system design and coordination: Engineers can avoid costly clashes before construction begins by integrating mechanical components with electrical and plumbing elements.

- Enhanced simulation and analysis: BIM MEP software allows engineers to simulate airflow, heat distribution, and energy efficiency, ensuring optimal system performance.

- Seamless collaboration: BIM-related software enables real-time collaboration between multidisciplinary teams, reducing miscommunication and project delays.

- Lifecycle management: From initial design to facility maintenance,

- can track system performance, predict maintenance needs, and optimise energy usage.

Why Mechanical Engineers Should Adopt BIM

Mechanical engineers play a crucial role in designing and maintaining essential building systems, including heating, ventilation, air conditioning (HVAC), plumbing, and fire protection. The integration of MEP in BIM ensures that these systems function optimally within a building’s overall design. As industries shift toward digital transformation, professionals skilled in BIM MEP software are increasingly sought after for their ability to improve project coordination and efficiency.

1. Enhanced Design Accuracy and Efficiency

Traditional mechanical system designs often suffer from inconsistencies and errors due to manual drafting. BIM modeling software allows engineers to create detailed, data-rich 3D models that minimise errors and streamline project execution. MEP BIM modeling ensures precise system integration and clash detection, reducing costly rework during construction.

2. Improved Collaboration Across Disciplines

One of the most significant advantages of BIM-related software is its ability to foster real-time collaboration between mechanical, electrical, and plumbing engineers, architects, and contractors. BIM mechanical engineers can share and update models seamlessly, ensuring all stakeholders can access the most accurate project data.

3. Optimised Energy Efficiency and Sustainability

With growing emphasis on energy conservation, BIM software enables mechanical engineers to conduct performance simulations and energy analyses. This helps design HVAC and plumbing systems that comply with sustainability standards, reducing energy consumption and operational costs over time.

4. Cost Reduction and Time Savings

Integrating BIM mechanical workflows into project planning allows mechanical engineers to identify potential design issues early, preventing costly modifications later. BIM MEP software also automates many design processes, reducing project timelines and increasing efficiency.

5. Increased Job Opportunities and Higher Salaries

The demand for professionals skilled in BIM mechanical is rising, with companies actively seeking experts in BIM modeling software for complex infrastructure projects. Job opportunities for mechanical engineers with BIM expertise are expanding, leading to higher earning potential. The BIM mechanical engineer's salary is significantly higher than that of traditional mechanical engineers due to the specialised skills required.

Key Applications of BIM in Mechanical Engineering

Building Information Modeling (BIM) has transformed mechanical engineering by improving design accuracy, collaboration, and efficiency. BIM mechanical engineers use BIM software to optimise HVAC, plumbing, and fire protection systems, ensuring seamless integration and reducing errors.

1. HVAC System Design

MEP BIM modeling enhances HVAC system efficiency by:

- Creating accurate 3D models for ductwork and piping.

- Optimising energy use and thermal comfort.

- Detecting and resolving clashes before construction.

2. Plumbing System Coordination

With BIM MEP software, mechanical engineers can:

- Design intelligent water supply and drainage models.

- Perform hydraulic simulations to ensure optimal flow rates.

- Reduce material waste through optimised layouts.

3. Fire Protection System Planning

BIM-related software aids in:

- Precise placement of fire suppression systems.

- Fire safety simulations for compliance.

- Reducing installation conflicts with other systems.

4. Clash Detection and Collaboration

BIM modeling software improves coordination by:

- Identifying conflicts between MEP components.

- Streamlining multidisciplinary collaboration.

- Reducing construction errors and rework.

5. Energy Efficiency and Sustainability

BIM software helps optimise energy performance by:

- Conducting energy modeling and simulations.

- Reducing carbon footprints and energy consumption.

- Ensuring compliance with green building standards.

Top BIM Software for Mechanical Engineers

Mechanical engineers utilise various BIM modeling software to enhance project efficiency:

1. Revit MEP

- Industry-leading BIM modeling software for HVAC, plumbing, and fire protection.

- Supports energy simulations and automated design documentation.

- Ensures seamless collaboration with architects and engineers.

2. AutoCAD MEP

- Ideal for drafting and designing BIM mechanical systems.

- Offers automated annotations and scheduling.

- Integrates with Revit MEP for a smoother MEP in BIM workflow.

3. Navisworks

- Essential for clash detection and project coordination.

- Enables 3D visualisation and real-time collaboration.

- Reduces design conflicts in MEP BIM modeling.

4. Trimble SysQue

- Provides manufacturer-specific content for precise system modeling.

- Enhances prefabrication and material efficiency.

5. Dynamo for Revit

- Automates repetitive tasks and optimises system layouts.

- Improves parametric modeling in BIM MEP software.

6. MagiCAD for Revit and AutoCAD

- Offers real-world product libraries for accurate MEP in BIM modeling.

- Advanced calculations for ventilation and heating systems.

Benefits of Using BIM for Mechanical Engineers

The benefits of BIM for mechanical engineers include:

1. Better visualisation

3D modeling aids in understanding complex mechanical systems.

2. Increased project efficiency

Speeds up design iterations and approvals.

3. Seamless collaboration

Ensures all stakeholders have access to real-time project data.

4. Enhanced job opportunities for MEP engineers

BIM expertise increases employability in top firms.

Career Opportunities & Salary Trends for BIM-Enabled Mechanical Engineers

With industries adopting BIM mechanical, the demand for skilled professionals is rising. Typical mechanical engineering job roles in BIM include:

- BIM Mechanical Engineer

- MEP BIM Modeler

- HVAC Design Engineer

- Plumbing & Fire Protection Engineer

- BIM Coordinator

The bim mechanical engineer's salary varies based on experience and location. In India, entry-level engineers earn around INR 4-6 LPA, while experienced professionals can command INR 12-20 LPA. Globally, salaries range from $60,000 to $120,000 per year.

How Novatr’s BIM MEP Courses Can Help Mechanical Engineers Excel in BIM Workflows

For mechanical engineers looking to upskill in BIM-related software, Novatr’s BIM MEP courses provide hands-on training in industry-standard tools like Revit MEP, Navisworks, and AutoCAD MEP. These courses help engineers master MEP BIM modeling, enabling them to secure top job opportunities for MEP engineers in the global market.

1. Comprehensive Training in BIM Modeling Software

- Learn industry-standard BIM software like Revit MEP, AutoCAD MEP, and Navisworks.

- Gain expertise in MEP BIM modeling for HVAC, plumbing, and fire protection systems.

2. Practical, Industry-Oriented Curriculum

- Hands-on projects to develop real-world BIM skills.

- Exposure to BIM mechanical workflows used in top firms.

3. Career Growth and Job Readiness

- Enhance job opportunities for mechanical engineers in BIM.

- Improve earning potential with a competitive BIM mechanical engineer salary.

4. Clash Detection & Coordination Skills

- Learn how to identify conflicts in BIM modeling software.

- Improve cross-disciplinary collaboration in construction projects.

5. Sustainability & Energy Efficiency Training

- Optimise mechanical system performance with BIM MEP software.

- Work on energy modeling to meet green building standards.

Conclusion

The role of a BIM mechanical engineer is becoming increasingly vital in the construction and infrastructure sectors. Learning BIM MEP software and mastering BIM modeling software can significantly enhance a mechanical engineer’s career prospects. With numerous job opportunities for mechanical engineers and competitive mechanical engineer salary trends, BIM expertise is a must-have skill for professionals aiming to excel in the industry.

Among the best options, the BIM Professional Program for MEP Engineers by Novatr stands out the most. For the latest updates, tools, and insights into the MEP and BIM industry, explore Novatr's Resource Page.

FAQs

Q1: What is BIM, and how does it apply to mechanical engineering?

Ans: Building Information Modeling (BIM) is a digital process that creates intelligent 3D models for designing, analysing, and managing building systems. In mechanical engineering, BIM enables engineers to design HVAC, plumbing, and fire protection systems with enhanced accuracy, real-time collaboration, and seamless integration with other disciplines, reducing costly errors and rework.

Q2: Why should mechanical engineers use BIM in their projects?

Ans: Mechanical engineers should use BIM to streamline MEP BIM modeling, improve design efficiency, and enhance project coordination. BIM MEP software enables engineers to optimise mechanical systems, detect clashes early, and integrate energy-efficient solutions. Additionally, BIM enhances visualisation, documentation, and project lifecycle management, ensuring cost-effective and error-free implementation of mechanical designs.

Q3: How does BIM improve mechanical system design and coordination?

Ans: BIM enhances mechanical system design by providing detailed 3D models, allowing engineers to analyse airflow, energy consumption, and equipment placement. It improves MEP in BIM coordination by detecting clashes between HVAC, plumbing, and electrical systems, ensuring seamless integration and reducing construction delays. Real-time collaboration also enhances communication between project teams.

Q4: What are the key benefits of BIM for mechanical engineers?

Ans: BIM's benefits for mechanical engineers include increased design accuracy, reduced material waste, and improved project efficiency. It also allows for better clash detection, energy modeling, and prefabrication, leading to lower costs and faster project completion. BIM also enhances job prospects, as the salary of a BIM mechanical engineer is higher due to increased demand.

Q5: How does BIM help in clash detection for mechanical systems?

Ans: BIM enables clash detection by identifying conflicts between mechanical, electrical, and plumbing components before construction begins. BIM software like Navisworks and Revit MEP allows engineers to visualise and resolve issues in the design phase, preventing costly rework and ensuring smooth installation of BIM mechanical systems in real-world projects.

Was this content helpful to you

.jpeg)