How Automation in Construction is Leading the Way for the AEC Industry

Table of Contents

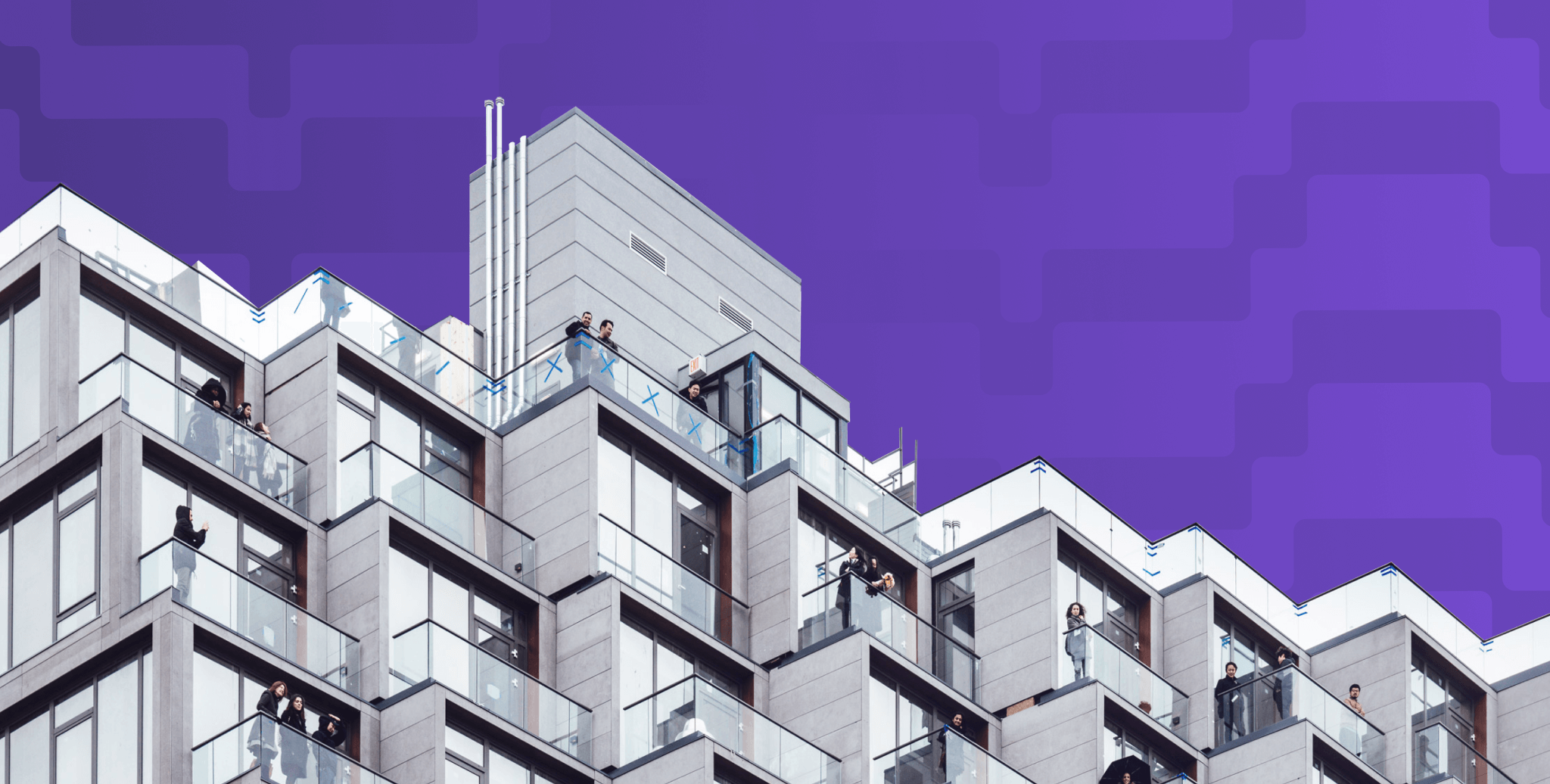

The building construction industry has always been labor-intensive, relying heavily on physical labor for activities such as digging, mixing, and carrying heavy materials. Traditional ways of construction are time-consuming, high-risk, and expensive. Despite these drawbacks, automation in construction remains underutilized. The adoption of machinery and equipment has played a role in modernizing the industry, but true automation in the construction industry still has a long way to go. By embracing construction automation, particularly automation in building construction, many labor-intensive tasks could be streamlined, leading to safer, faster, and more cost-effective processes.

What is Automation in Construction?

Automation in the AEC Sector is the integration of advanced technologies, digital tools, and robotics in the working of the Construction industry to enhance efficiency, minimise clashes and reduce cost. It makes use of various technologies like Generative Artificial Intelligence, 3D printing and even drones. It is all used to streamline construction at different phases. As a process, it can be used throughout construction like in the creation of exoskeletons and autonomous machinery along with post-construction, in management like predictive analytics.

How can Automation in Construction be Beneficial?

In recent years, several new construction technologies have emerged that have the potential to revolutionize the industry. Automation in construction can greatly increase productivity and efficiency on job sites. By using automated equipment and processes, AEC companies can complete projects much faster than with traditional labor-intensive methods. This means that projects can be completed on time or even ahead of schedule, which can lead to cost savings and increased profitability. Additionally, automation can improve the quality of work by reducing human error and ensuring that tasks are performed consistently and accurately.

In recent years, several new construction technologies have emerged that have the potential to revolutionise the industry. Automation in the construction industry can greatly increase productivity and efficiency on job sites. By using automated equipment and processes, AEC companies can complete projects much faster than with traditional labor-intensive methods. This means that projects can be completed on time or even ahead of schedule, which can lead to cost savings and increased profitability. Additionally, automation can improve the quality of work by reducing human error and ensuring that tasks are performed consistently and accurately.

Here are five key benefits:

-

Creates a Streamlined Bidding Process

Automated AI bots can keep various departments and teams on the same page upon discussed quotes. Moreover, it results in the automation in building construction projects by keeping the stakeholders informed.

-

Increases Productivity

With 72% of workers saying it takes longer than the anticipated construction time. Construction automation can help regulate it. It eases out the project through the right management.

-

It Reduces Cost

Construction Automation helps reduce costs as it cuts on repetitive tasks. Moreover, automation in the construction industry eases the process and enhances efficiency.

-

Client Experience is Improved

Automation in the AEC sector helps improve transparency. Thus improving the client experience. Through a single workflow in the form of automation in the construction industry, the client can keep track of the current status of the project along with expected expenditure.

-

Improving Employee Satisfaction

Automation in building construction reduces the workload. Putting more emphasis on efficiency than clocking in. This in return improves the quality of work by the employees.

How New-Age Technologies Can Be Integrated in Construction Projects to Achieve Automation

Technology integration can make construction processes simpler, more efficient, and speedy. Construction automation is one of the key technologies that are redefining the AEC industry. Mentioned below are the key technologies that are transforming the sector and how they can be integrated into projects.

Computational Design

Computational design can help achieve automation in construction by enabling architects and designers to create complex and customized designs with greater ease and accuracy. Computational tools involve the use of computer algorithms and software to generate and optimize building designs. By using computational tools, architects and designers can analyze and optimize building designs in real-time, based on a range of factors such as energy performance, structural integrity, and occupant comfort. This enables faster and more accurate design iterations, which can help reduce design errors and improve the quality of the final product.

Also Read: Top AEC Computational Design Trends in AEC in 2025

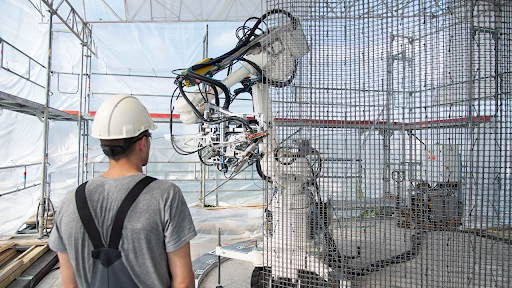

Robotic Vehicles

Robotic vehicles find application as autonomous earthmoving equipment. These machines can be used for tasks such as excavation, grading, and soil compaction. Further, autonomous equipment can operate around the clock, which can help accelerate project timelines and improve productivity. Another application of robotic vehicles in construction is unmanned aerial vehicles (UAVs) or drones. Drones can be used for a range of tasks, such as surveying and inspecting job sites, monitoring progress, and transporting materials. Drones can capture high-resolution images and videos of job sites, which can be used to create detailed maps, 3D models, and point clouds. This data can help construction companies optimize their workflow, identify potential issues, and improve safety on job sites.

Pre-Fabrication

Prefabrication involves the manufacturing of building components in a controlled factory environment, which can then be transported to the construction site for assembly. By using prefabrication, construction companies can reduce on-site labor requirements, improve quality control, and reduce waste. Prefabrication also enables faster construction times, as building components can be produced and assembled simultaneously rather than in a sequential process. One of the main advantages of prefabrication is its potential for modular construction. Modular construction involves the use of prefabricated building modules that are assembled on-site to create a complete building. It enables greater customization and flexibility, as building modules can be easily modified or added to accommodate changing needs.

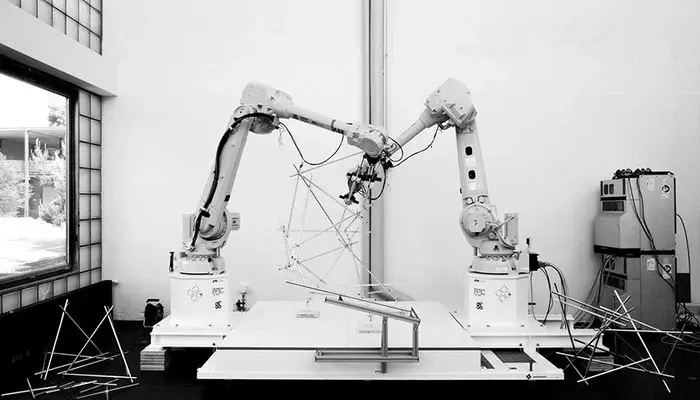

Digital Fabrication

Digital fabrication involves using computer-controlled machines, such as 3D printers and CNC machines, to create parts and components for construction projects. These machines can create highly detailed and complex shapes with a high degree of accuracy and precision. By using digital fabrication, construction companies can produce parts and components much faster and with greater consistency than with traditional manufacturing methods. This can help reduce construction time and costs while improving the quality of the final product. Additionally, digital fabrication can reduce waste and improve resource efficiency by minimizing material waste and optimizing material usage.

Digital Building Management

Digital Building Management (DBM) involves the use of digital sensors, data analytics, and automation systems to monitor and control various building systems, such as lighting, HVAC, and security. By using DBM, building operators can optimize building performance, reduce energy consumption, and improve occupant comfort. DBM can also help identify potential issues before they become major problems, which can reduce maintenance costs and prolong the life of building systems. Smart building automation involves using sensors and automation systems to automatically adjust building systems in response to changes in occupancy, weather conditions, or other factors.

Challenges of Introducing Automation in Construction

Introducing automation in architecture is a challenging task due to several reasons. Firstly, the architecture industry heavily relies on manual labor, and integrating automation requires a significant shift in the mindset of architects and engineers. It requires them to learn new skills and adapt to new technologies, which can be a time-consuming and expensive process.

Secondly, the integration of automation in architecture requires a significant investment in infrastructure, software, and hardware. Implementing automation in architecture requires a thorough understanding of the industry and its complexities. This knowledge is crucial for the development of effective automation systems that can meet the specific needs and requirements of the industry. Additionally, the industry is notoriously slow to adapt to change, which has further hindered the adoption of new construction technologies.

However, the potential benefits of automation, such as increased efficiency, accuracy, and cost savings, make it an exciting opportunity for the architecture industry to explore.

In Conclusion

As the construction industry continues to evolve and face new challenges, the integration of automation is likely to become increasingly important. While it may take time to overcome the challenges and fully realize the benefits of automation in construction, the potential for increased productivity, reduced waste, and improved safety make it a valuable investment for the future of the industry. By embracing automation, the construction industry can achieve new levels of efficiency, safety, and sustainability, paving the way for a brighter future.

If you’re an architect or engineer who’d like to learn automation for advancing your career, do check out Novatr’s Master Computational Design Course. In this course, you can understand computational theory, master advanced tools, and industry workflows, build your specialization and graduate with a professional certification by enrolling in this course. You’ll learn through interactive live sessions with an international panel of experts from top-tier firms who serve as your mentors. Novatr also provides career guidance and placement support to help all participants secure the best job opportunities.

Thanks for connecting!

Thanks for connecting!

.png)

-1.png)