6 min read

October 31, 2022

Table of Contents

Thanks for connecting!

Thanks for connecting!

Table of Contents

Digital fabrication technology has changed the way we produce and construct, or even design, thanks to the digital and industrial technology available today. Many products of the past had standardised forms and functions, but now, with digital fabrication equipment and software, we can customise a product and manufacture it easily.

There are several digital fabrication technologies available today, some much more conveniently than others. For example, we can find laser cutting machines and 3D printers commonly in many architecture schools. Acclaimed architecture schools like MIT and AA have even more advanced tools for research by students.

Despite it being a fairly old technology, it has only taken off in recent years. Many industry professionals are still in the dark about digital fabrication as they lack exposure to such technology. Nevertheless, it is important to keep up with the industry trends and this is one we should all be familiar with.

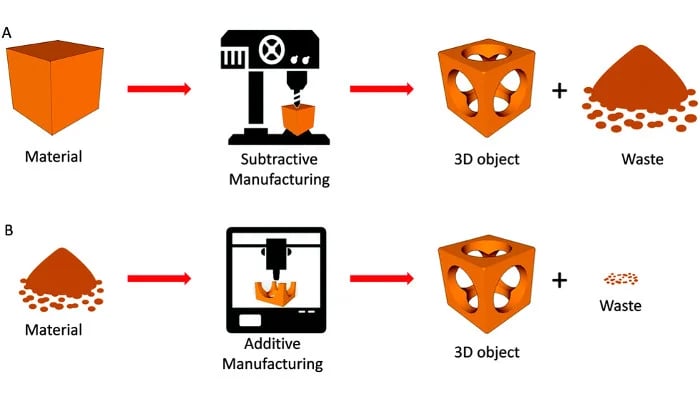

Digital fabrication in the AEC industry can be easily categorised into two: Additive Manufacturing and Subtractive Manufacturing. Under these two categories, there are a number of fabrication technologies used by architects and designers, the most common of each category being 3D printing and laser-cutting. Let us first take a broad look at what Additive and Subtractive Manufacturing are, before delving into each technology.

Additive manufacturing is a digital fabrication technology wherein the machine ‘adds’ layers on layers to create a product. This fabrication process is also known by another name – 3D printing.

Additive manufacturing has been around since the 1980s, used in rapid prototyping to create scale models. However, these products only served as prototypes with no functionality. The advance in additive manufacturing technology nowadays has produced functional objects which can be used in machinery or as furniture. There are so many fabrication materials available now, and we can conveniently manufacture objects in steel, plastics, ceramics, biomaterials and other polymer compounds.

Many of these products are designed in parametric modelling software like Rhino 3D. Check out these 10 Fascinating Projects Created Using Rhino 3D ranging from a small furniture to a whole building.

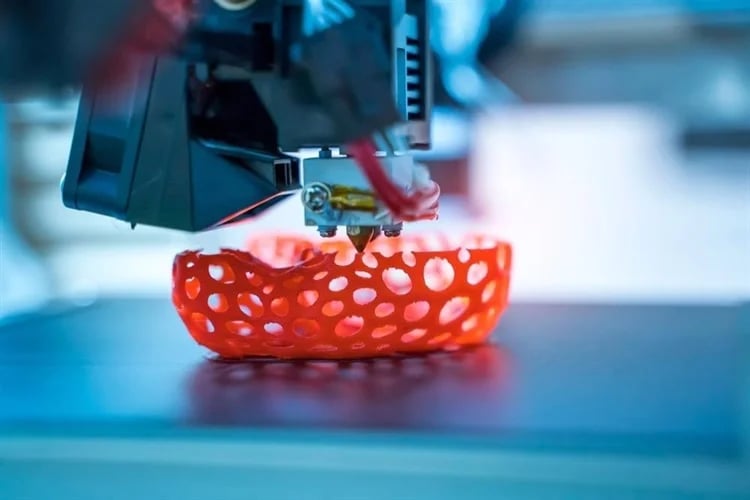

In a typical 3D printing process, lasers, electron beams or thermal heads are used to melt the material. It is then deposited through a nozzle onto the base platform in layers. The object is ready to be taken out once it has been left to dry. Such a method is also known as Material Extrusion.

Materials we use in construction and fabrication are becoming more advanced. Here are 10 Trendy Advanced Construction Materials You Should Know that will soon be common in the industry.

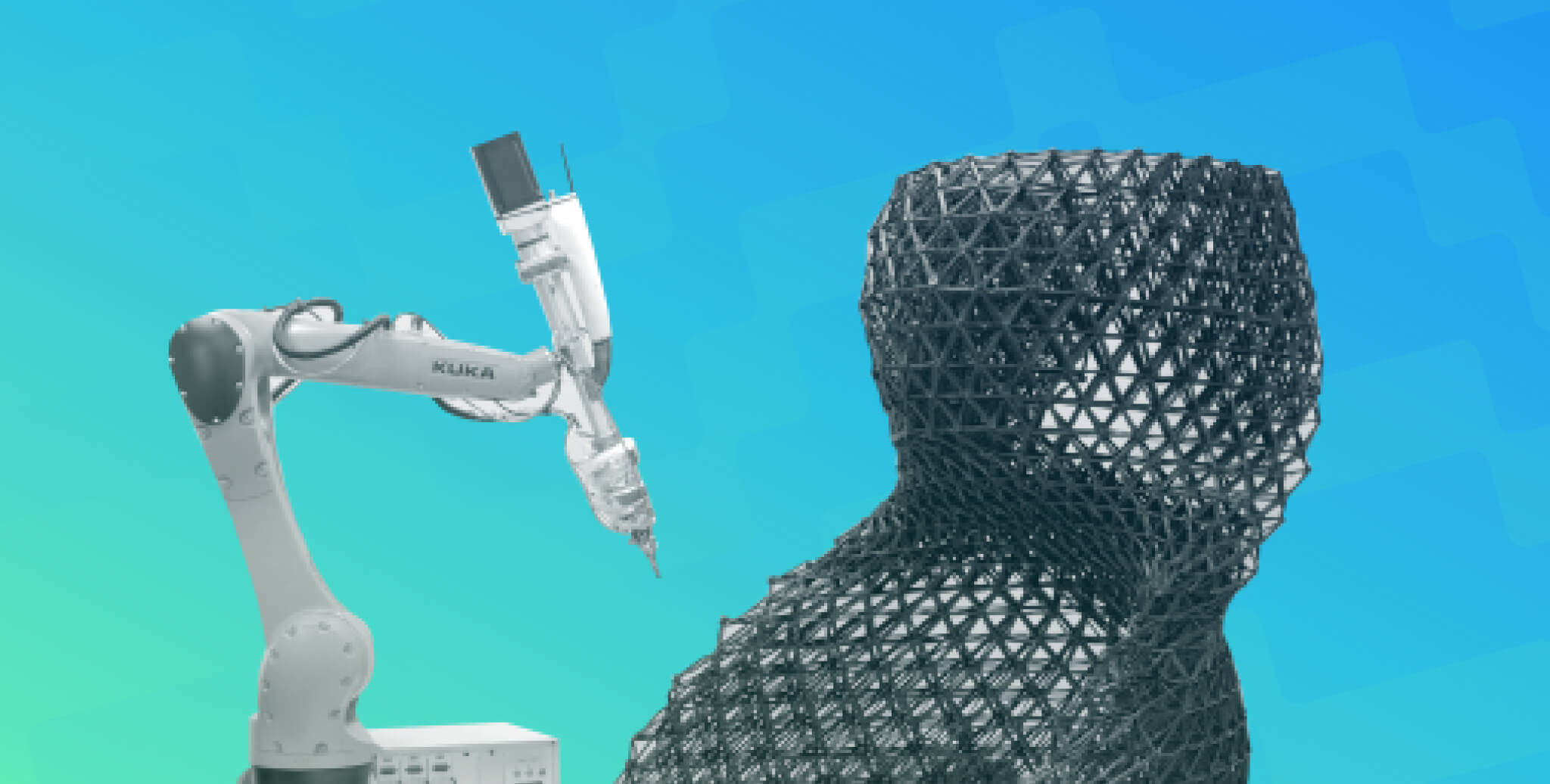

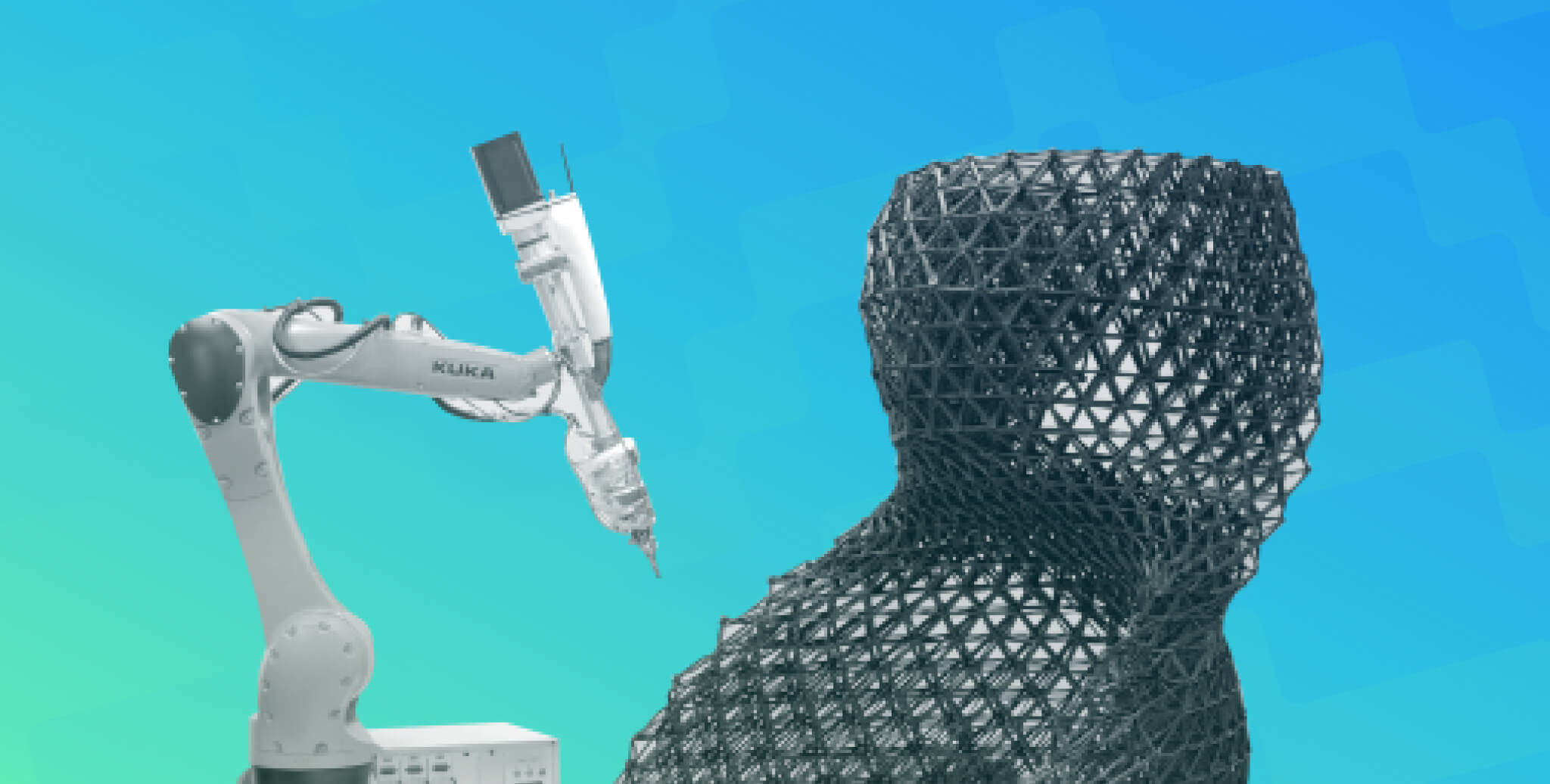

A more complex process of material extrusion is referred to as Direct Energy Deposition. In material extrusion, the nozzle only lays the material in one direction or axis. On the other hand, direct energy deposition works by using a four- or five-axis arm that deposits the melted material.

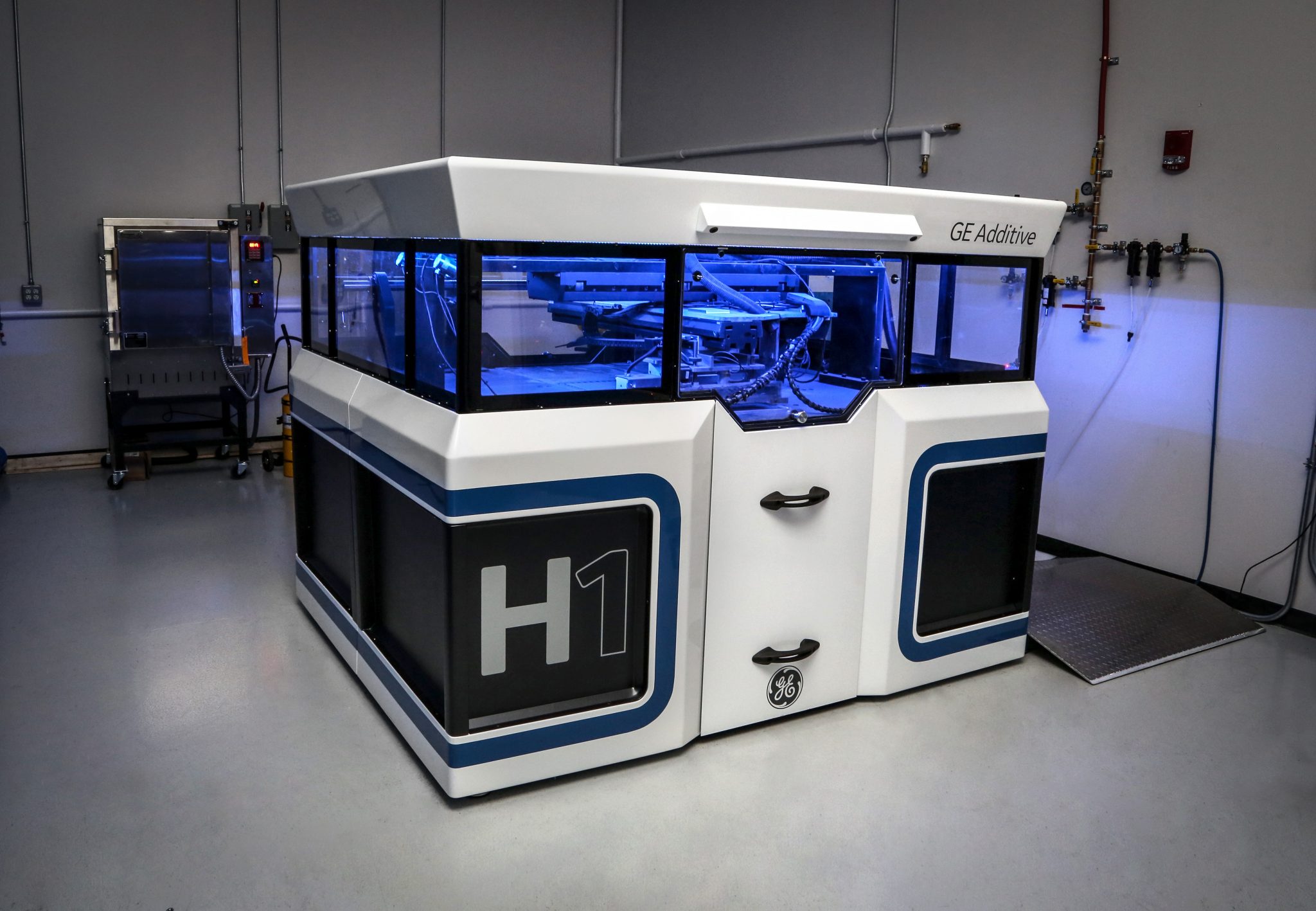

While other 3D printing uses resin of different materials to print, binder jetting uses powder materials and a liquid binding agent to build up layers. The fabrication equipment, with an ink-jet nozzle, deposits the powder onto the base platform in layer by layer based on the CAD file used until the shape is complete. The manufacturers can preset the parameters which essentially automates the fabrication process. One thing to note is that the type of material used should be taken into account when planning the CAD file as the height of a layer can vary according to the material. The most common materials used in this digital fabrication technology are metals, usually alloys like steel, and ceramics.

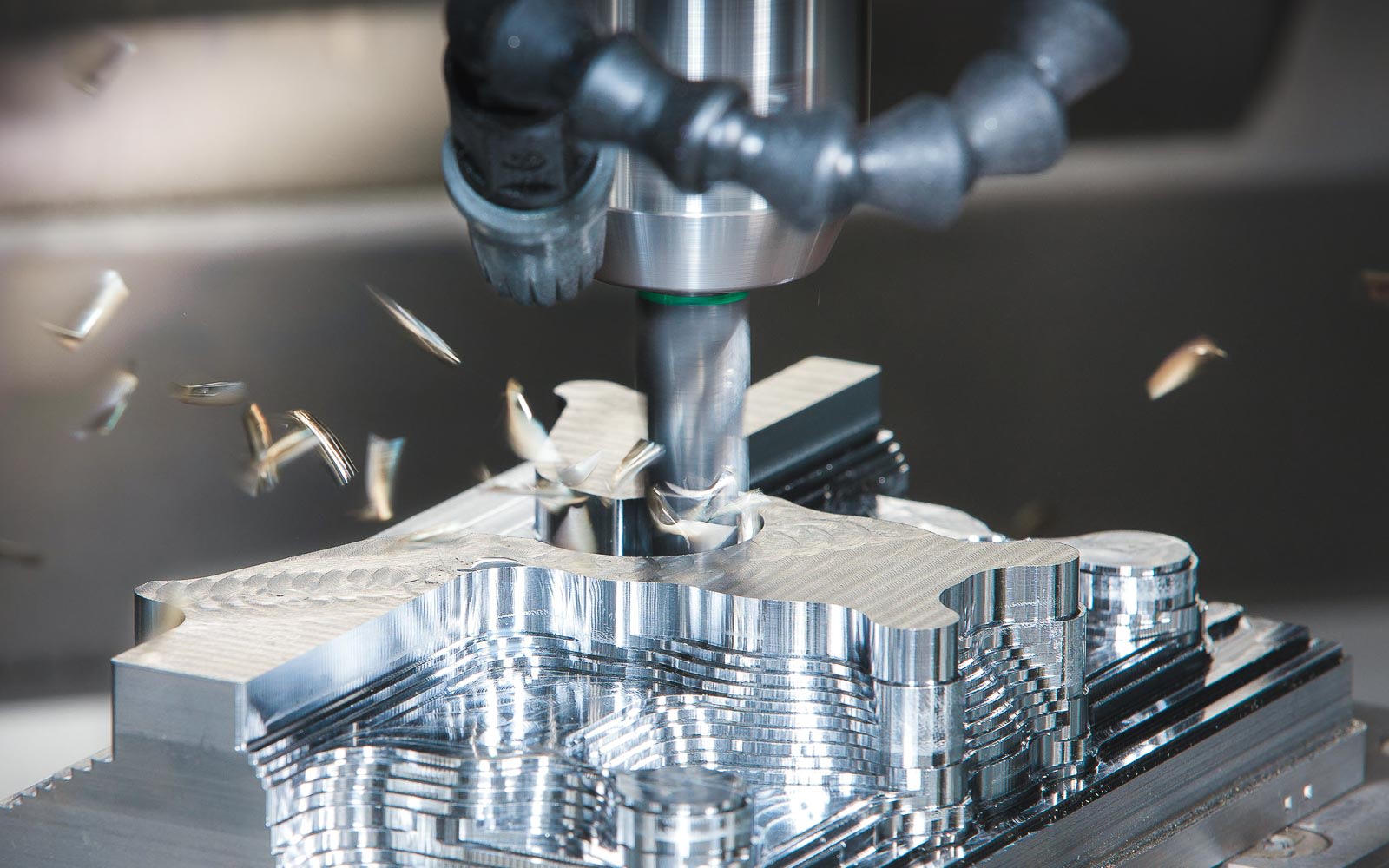

Think of subtractive manufacturing as a sculpting process; but instead of a sculptor, it is the computer software and machine that do the work. As the name suggests, it works by removing excess material to give shape to the object. Generally considered an umbrella term, it compasses all processes that cut, engrave, bore and drill to remove material. Most of these fabrication processes come under CNC (Computer Numerical Control) technology.

CNC stands for Computer Numerical Control, a subtractive manufacturing process that makes use of computerised control for operation. CNC milling is a common example of CNC machining processes where the computational system controls the rotary cutting tools to chip away unwanted portions of a material to create a desired shape. The process is feasible with several types of materials including plastics, metals or even 3D printed materials. Many industries, such as industrial design, electronics and automotive, have made use of CNC machining for manufacturing processes as it only requires CAD or CAM drawings.

It is now common to find laser-cut products in the commercial sector ranging from small household items to furniture. Similar to CNC milling, most laser cutting processes require a CAD file which will be placed in the laser cutter software. When the machine starts operating, the high-intensity laser beam falls onto the material.

Cutting a material is not the only function of a laser cutter; we can also engrave at different depths by adjusting the intensity of the laser and the distance between the nozzle and the material. As it is a relatively easy and fast process, many designers, entrepreneurs and even students can create their own products in large quantities in a short time.

If you are not sure what CAD file is and how it is different from BIM, check out CAD vs BIM.

In both additive and subtractive manufacturing, only a CAD file is needed. Then the software, different for each fabrication process, will translate it to data understandable by the machine. Once the file has been sent to the fabrication equipment, it will start the process and rarely, any additional human input is necessary throughout.

Architects and designers can use parametric modelling tools to create complex models which will then be exported to CAD format. Thus, it is common to find even the most complex forms digitally fabricated.

The duration of production in each digital fabrication technology varies depending on the type of process, the size and complexity of the objects. It can take anywhere between a couple of hours to days.

Head to Novatr’s Resources page to stay up to date with the different technological innovations, insights and career paths in the AEC industry.

Subscribe to Novatr

Get articles like these delivered to your inbox every two weeks.

.png)

Ready to skyrocket your career?

As you would have gathered, we are here to help you take the industry by storm with advanced, tech-first skills.

We’ll send you a nice letter once per week. No spam.

©2023 Novatr Network Pvt. Ltd.

All Rights Reserved